“3D Printing Revolution: Mastering Color and Texture Through Ironing Techniques”

In the thrilling realm of 3D printing—a space where creativity and technology intersect like fireworks on a dark, starry night—there's a fresh wind blowing in from the research halls of MIT and Delft University of Technology. Hold onto your hats, because we’re about to dive into a revolutionary technique known as "speed-modulated ironing." This isn’t merely a curious concept spinning in the minds of academics; it’s a game-changer in how color, texture, and shade can be manipulated in 3D printed objects. You might even say it’s a leap into the future of printing that could bring vibrant and tactile creations to life right before our very eyes.

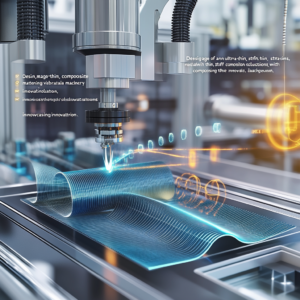

So, what’s the deal with this speed-modulated ironing technique? Let’s break it down, while keeping it entertaining because education doesn’t have to be boring, right? Imagine a painter with a palette of colors, but instead of brushes, you've got a 3D printer armed with a dual-nozzle system. The wonders of science allow it to deposit a heat-responsive filament through one nozzle while the other nozzle—an empty bystander—glides over the surface. This second nozzle isn't just lolling about; it's actively heating the material beneath it, provoking reactions that alter its color, shade, or texture. It’s like a magician waving a wand, making the object shimmer in ways we’ve hardly dared to dream!

Now, let's touch on the nuts and bolts of how our dual-nozzle dynamo operates. The secret lies in that oh-so-important temperature control. Just as one might gently pass a finger over a hot flame, the speed with which the second nozzle moves directly correlates to the filament's temperature. Slower movements? Higher heat. Quick passage? Lower temperature. This method gives researchers the ability to finely tune not just the hue of the material but also its very feel and look, bringing forth a sensory experience that traditional printing has failed to achieve.

And who wouldn't want to revel in the advantages of this miraculous technique? Traditional methods of 3D printing can feel painfully inefficient, often throwing away more materials than they produce. Speed-modulated ironing elegantly sidesteps that outdated model by using a single material, thus minimizing waste while maximizing creativity. In the blink of an eye (okay, maybe not quite that fast), complex color and texture combinations can emerge from the printer, freeing designers from the tedious post-processing stage that typically plagues 3D creation.

But hey, comparing this to its 3D printing relatives gives even more shade to our speed-modulated hero. Take Fused Deposition Modeling (FDM), for instance. Sure, it’s popular, like a well-worn sneaker, but when it comes to color and texture control, it’s about as exciting as a plain white canvas. You can slap on some colored filaments, but mixing colors and crafting those intricate textures? Yeah, good luck with that. Move over to Multi Jet Fusion (MJF), and things get a bit fancier with precise color reproduction; however, it comes at a dearer price and complexity that would make anyone's head spin. And then there’s Stereolithography (SLA), revered for its astonishing resolution and smooth finishes, which can make quite a show of color mixing, but it fizzles out when it comes to useful texture control. In the whimsical world of 3D printing, speed-modulated ironing steals the spotlight, if I may be so bold.

The implications of this new technique are dizzyingly vast, paving the way for innovation across industries that span everything from product design to the art world. Product designers are no longer confined to the drab prototypes of yesterday; they can whip up creations that tantalizingly resemble the final product, color and texture intact. Artists and hobbyists, prepare to be dazzled as the door swings wide open to bespoke and intricate designs that invite tactile engagement. And then there’s the realm of research and development—which could see unprecedented acceleration thanks to the ability to prototype materials with specific properties right from the get-go.

As we close in on the conclusion, it’s evident that the speed-modulated ironing technique represents a pivotal moment in the story of 3D printing. We're not just talking advancement; this is a full-bodied evolution, granting creators an extraordinary level of control over their materials. As this technology continues to unfurl, it opens the door to a wonderland of possibilities.

Feeling as engrossed by this technology as I am? Want to be the first to know about the marvels emerging from the world of neural networks and automation? Subscribe to our Telegram channel: @channel_neirotoken, and let's embark on this epic journey together!