3D printers leave hidden ‘fingerprints’ that reveal part origins

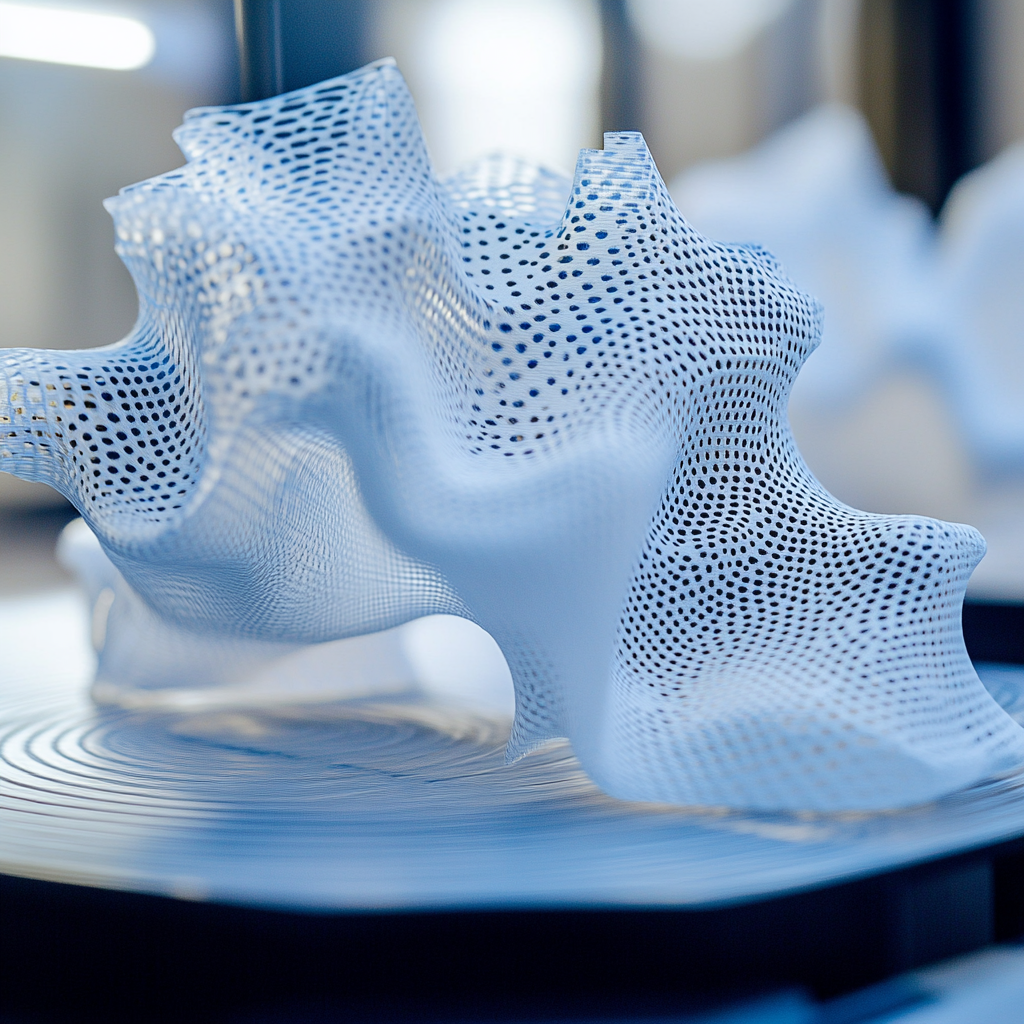

In the realm of innovation, tissue-thin lines often separate daydreams from concrete realities. A new frontier has emerged, one that fuses cutting-edge technology with an art form most people associate with DIY projects and plastic figurines. We're talking about 3D printing—the digital alchemy wherein machines conjure solid objects from mere thoughts and digital designs. And now, dive deep with me into a delightful twist: a groundbreaking discovery revealing that every 3D printed item has a secret signature, much like a human fingerprint.

Picture this: a world where every gadget, trinket, and prototype bears an invisible mark that tells its tale of creation. Those wispy lines and shapes you see in your homemade 3D printed vase? They’re more than just aesthetics—they're part of its DNA. This intriguing notion centers on the notion that every machine, regardless of how identical they seem, leaves its own special print on every object it produces. It's not a figment of your imagination. This revelation comes courtesy of brilliant minds like Bill King and his team from the University of Illinois, Urbana-Champaign.

So, what's the magic? Researchers have found that each 3D printer, even when utilizing the same designs and materials, injects its unique characteristics into the prints. Curious to know how they figured this out? They used an artificial intelligence system, no less—clever, isn't it? Trained on a whopping 9,192 images of parts birthed by 21 different machines spanning six brands and four distinct methods of fabrication, the AI can now identify a product's machine with an astounding accuracy of 98%. Picture analyzing just a mere square millimeter of a printed part, and voilà! You possess the abilities of a forensic guru.

Let’s chew that over for a second. This technological wizardry has profound implications across industries—for manufacturing, it’s akin to striking gold. Ever worried about that spicy risk of counterfeit components slipping through quality checks? Forget sleepless nights; manufacturers can now monitor suppliers, validate processes, and establish a level of accountability that could wipe out the lesser-quality fakes. It’s practically insurance in the twisted and often precarious world of commerce.

But hold your horses, as we trot into another riveting realm: forensic science. Here, the potential is equally electrifying. Criminals often leave behind more than just fingerprints; in our 3D printing era, they could also leave behind unique machine signatures. This revolutionary finding can transform investigations—detectives could trace back evidence to the specific machine that produced it. Imagine the power: rather than merely matching class characteristics shared by similar models, forensic science can now sift through the layered complexities of 3D printed objects, pinning down who’s responsible for what.

The implications of this discovery curve around like a well-formed spiral on a 3D printed design. Counterfeit prevention and supply chain security take a step forward, fostering an industry ripe with ethical discussions and the need for responsible practices. As the landscape of additive manufacturing grows more intricate, it's crucial that we balance our strides forward with a thoughtful gaze back toward the ethical responsibilities our innovations impose. We've leaned heavily on technology in the past—let’s strive now to wield it with wisdom.

Take a moment to contemplate the fabric of this new existence. 3D printing, a world previously dominated by DIY enthusiasts, hobbyists, and industrial manufacturers, is now dawning a new cloak woven with uniqueness and security. It'll take time to fully comprehend the expansive horizon this opens up, as the once simple act of printing an object transmutes into a thoughtful act that meshes with accountability.

And as we meander through this ever-evolving narrative, there's something immensely rewarding about being a part of this thrilling journey. It’s not just about keeping your gadgets in order or ensuring your art piece is truly yours. It’s about access to a cutting-edge validation system, one that introduces peace of mind to an industry that has often had more question marks than certainties.

To wrap it up, the future of 3D printing lies beautifully entwined with both creativity and responsibility. It encourages us to ponder: how can we continue to push the boundaries while maintaining the integrity of our creations? Sustainable innovation is the key; we simply cannot afford to live in a world where our advancements come at the cost of accountability.

Intrigued by this brave new world of unique identifiers and ethical considerations? Want to stay up to date with the latest news on neural networks and automation? Subscribe to our Telegram channel: @channel_neirotoken. After all, knowledge is the best armament in navigating these complex landscapes. So, let’s forge ahead together into the realm of 3D innovations and beyond!