Innovative Electrochemical Reactor Harvests Lithium from Brine to Meet Rising Demand

In today’s electrifying era of renewable energy, where eco-friendly dreams intertwine with ongoing technological innovations, lithium has become a hot commodity—quite literally. Your electric vehicle or next-gen gadget wouldn’t buzz without it. But extracting this precious metal from brine brimming with competing ions? That's no walk in the park. Traditional methods? A mixed bag of high energy demands, environmental pitfalls, and an intricate song-and-dance when it comes to separating lithium from its pesky companions. Enter the scene, a brainchild of brilliance from Rice University—a novel electrochemical reactor—destined to shake things up in lithium extraction.

Let’s take a step back and peek at the dark side of conventional lithium extraction. Picture a world where lithium is extracted from natural brine solutions found in geothermal hotspots. The catch? These brines are a veritable medley of ions like sodium, potassium, magnesium, and calcium—all eager to step in when lithium gets the VIP treatment. The music of chemistry plays its own staccato, creating disruption because, well, lithium and these other ions don’t exactly like to play nice. Achieving that crucial high selectivity in separation techniques? It feels about as straightforward as a cat trying to swim. No wonder energy bills throw tantrums, and chemical waste is on a rampage.

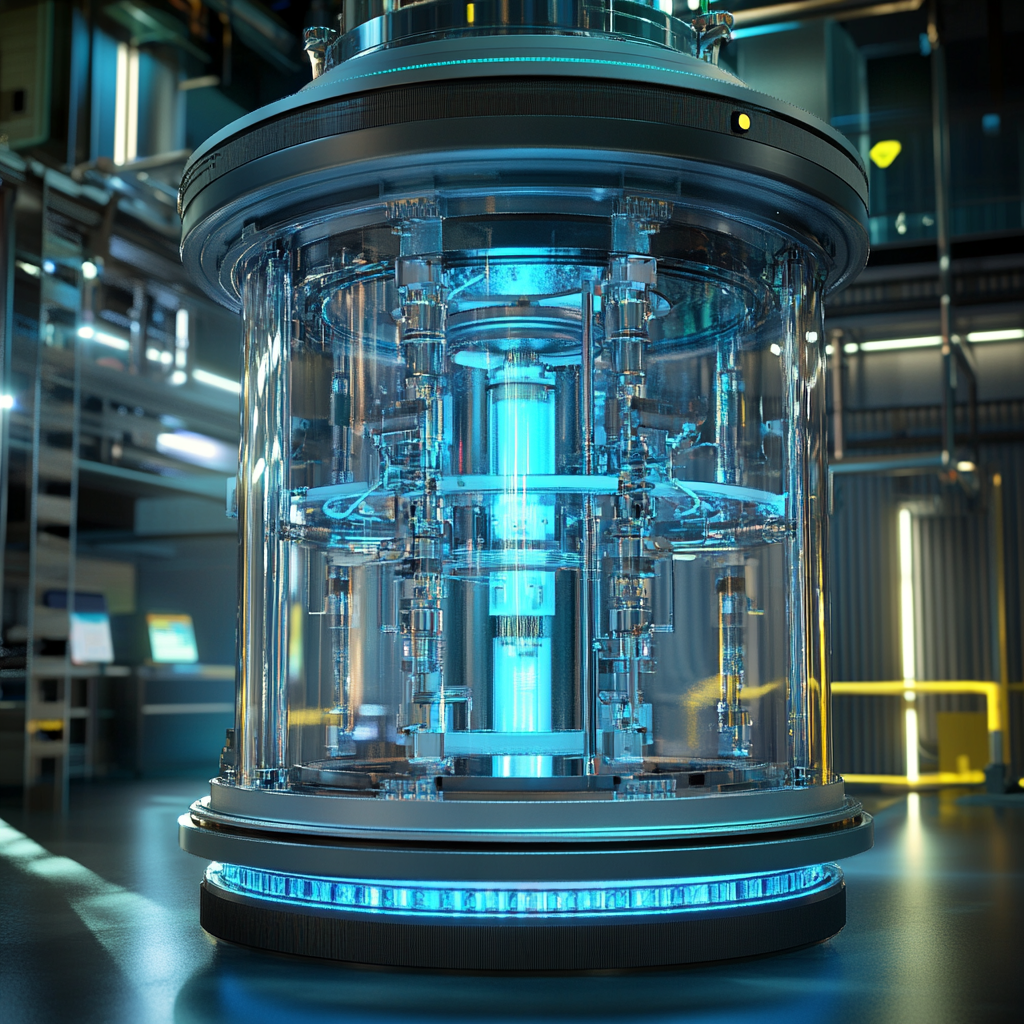

But hold onto your hat; here comes a paradigm shift! The brainchild of Lisa Biswal and Haotian Wang, this radical electrochemical reactor is as glamorous as it is functional. It’s not just an upgrade—it’s a full-blown transformation, promising to conquer the chaos of brine extraction with a wave of efficiency and selectivity.

What’s so special about this reactor, you might ask? Oh, let’s spill the secrets. To start, we will mention its dazzling decoupled, membrane-free design. Traditional electrochemical cells tend to act like the divas of the party—requiring membranes that foul up and need babysitting. Our newly minted reactor? It skips the membrane fuss, smooths out the process, and keeps lithium close without the counterion drama. Talk about conspicuous efficiency!

And if you think that's where the charm ends, think again. We're talking iron-phosphate electrodes—the unsung heroes in the lithium saga. These beauties show remarkable selectivity for lithium ions and separate them with the finesse of a master conductor leading an orchestra. They understand that in the world of brine, competition is fierce, and being selective is the name of the game.

Now, don’t be fooled! This reactor isn’t just some flashy gadget set to gather dust. It rolls with high efficiency and stability. We’re talking about minimizing hazardous byproducts like chlorine gas; something traditional electrochemical processes would churn out like confetti at a parade. So goodbye to those ghastly byproducts—this reactor is here to honor the planet while it extracts lithium like a pro.

So how does this brainy device work its magic? Imagine the dance it conducts every day:

- It opens its arms to a brine solution, brimming with a wild variety of ions, including our star, lithium.

- Then, the reactor unleashes an electrochemical potential that attracts lithium ions to the iron-phosphate electrodes like moths to a flame.

- Those precious lithium ions get a taste of glorious separation from the crowded ion party, achieving purity that even a monk would admire.

- Ta-da! The extracted lithium is collected and sent off to join the ranks of rechargeable batteries, ready to power our renewable future.

But let’s not gloss over the ramifications of such a groundbreaking invention. We’re on the brink of a new age where lithium extraction just got a major facelift. For starters, imagine a world of renewable energy storage—where the demand for batteries in electric vehicles and renewable energy tech isn’t just met, but supercharged.

Ain’t it sweet? The cherry on top? This method isn't just a feather in the cap for lithium extraction—it’s a clear win for environmental consciousness. Picture reduced energy consumption and fewer noxious byproducts. Mother Earth gets her well-deserved respite while we power our tech with finesse.

And let’s not sideline the economic implications. With the elegant simplicity and sheer efficiency baked into this reactor’s design, we’re likely to see cost reductions in lithium production. That’s akin to finding an extra burger in your takeaway bag—all gains and no pains.

In summary, what we’re looking at with this innovative electrochemical reactor from Rice University is not merely an exciting development; it's a full-on game changer. It swoops in like a superhero with a promise to elevate lithium extraction, taking it from the troubles of traditional methods into a new realm of sustainability and efficiency. With the world’s eyes set on transitioning towards renewable energy and electric travel, this technology shines as a beacon of hope for a better, greener future.

So the next time you hop in your electric vehicle or plug in your battery-operated device, remember the remarkable journey of lithium from brine to battery—made smoother thanks to a revolution that’s blazing trails in sustainability.

Want to stay up to date with the latest news on innovative technologies and sustainable energy solutions? Subscribe to our Telegram channel: @channel_neirotoken