Animal Power Infuses Med Robotics: 3D Printed Liquid Metal Shape-Shift

Giving Animal Strength to Medical Robotics: The Revolution of 3D Printing with Shape-Shifting Liquid Metal

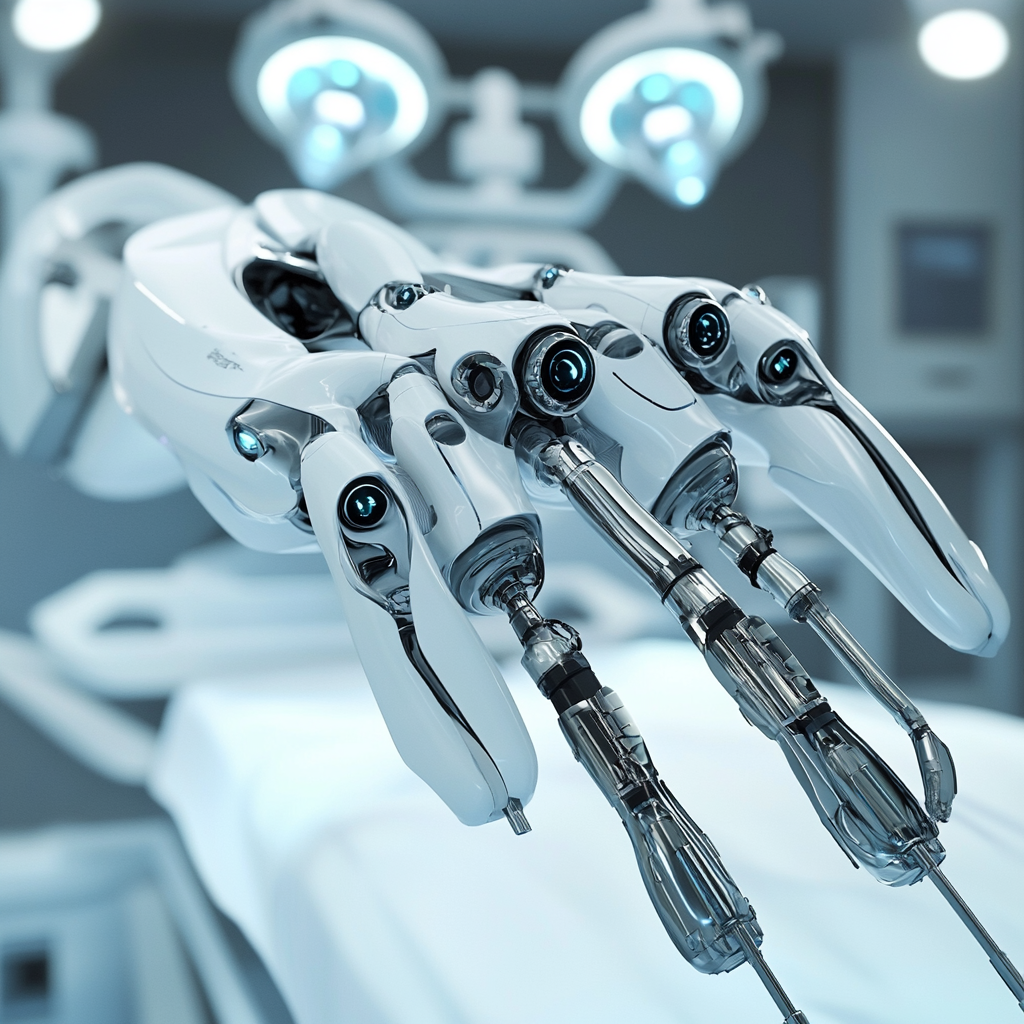

In the exhilarating world of medical robotics, a truly sensational leap forward is changing the game completely—think about giving robots a dash of animal strength and agility! Yes, you read that right. Researchers at the University of Queensland are steering the ship toward a future where robots are not just bits of metal and code, but beings with the flexibility and endurance reminiscent of our furry friends on Earth. This all revolves around a mind-boggling approach that involves 3D printing with a material that sounds like it belongs in a sci-fi flick—shape-shifting liquid metal.

The Science Behind the Innovation

Under the bright Australian sun, genius professionals like Dr. Ruirui Qiao and her team from the Australian Institute for Bioengineering and Nanotechnology (AIBN) are cooking up something remarkable. They’ve channeled the very essence of mammalian movement, harnessing the soft power of spherical liquid metal nanoparticles combined with gallium-based nanorods, which resemble rigid little soldiers ready to assemble. Upon diving into the deep end of this technological pool, you’ll discover that this innovative hybrid material mimics the intricate web of bones and muscles found in animals. Yes, it's like turning robots into sleek, agile creatures! The blend provides the robots with newfound prowess—strength and efficiency that can amplify the robotic components, making them the ultimate partners in rehabilitation and medical settings.

Applications in Medical Rehabilitation

Now, let’s talk about why this matters. Dr. Qiao and her squad aren’t just in it for the glory; they’re making strides that can significantly change lives. The tunable gallium-polymer composite they’ve created could very well redefine the landscape of medical rehabilitation. Imagine prosthetic limbs that don’t just look human but move like them, gripping things with the precision and sensitivity that could bring tears to your eyes. When exposed to stimuli like heat or infrared light, these ingenious materials can morph into various shapes, adapting dynamically based on what is needed. It’s like having a Swiss Army knife, but way cooler—this versatility could make all the difference in the medical field.

Overcoming Traditional Manufacturing Challenges

What gets the heart racing here? Traditional manufacturing techniques have often struggled like that one buddy who can’t take the hint during karaoke. They become bogged down by the rigid material selection and the hassle of complex processes that just complicate things. But Dr. Qiao’s ingenious method invites simplicity to the scene, transforming the way these advanced materials are fabricated. Rapid production of hybrid structures becomes a walk in the park, opening the floodgates for all kinds of innovative practices. It's all about elevating the game of soft robotics and channeling the spirit of efficient designs.

Rapid 3D Printing with Liquid Metal: A Parallel Innovation

While Dr. Qiao delights in the possibilities of enhancing our health and resilience, across the ocean, those slick minds at MIT are also diving into the deep end of liquid metal printing (LMP). This fresh approach allows for the rapid production of sizeable metal parts—think furniture pieces—crafted in mere minutes! Yes, you can crank out a table leg or a chair frame faster than most of us can decide what to have for dinner. The process involves pouring molten aluminum into a bed of tiny glass beads, creating a perfectly shaped form that cools and solidifies faster than you can say “manufacturing revolution.”

Key Features of Liquid Metal Printing

Let’s get to the meat of it—all the things that make LMP such a dazzling slice of innovation:

-

Speed and Scale: Need it fast? Look no further. LMP zooms along at speeds at least 10 times faster than traditional metal additive manufacturing, making it cheaper to produce large parts while lowering costs. Who doesn’t love saving money?

-

Material Efficiency: Say goodbye to the days of dealing with melted-on problems that create structural headaches. This process keeps the aluminum molten, ensuring smooth sailing without the messy remelting.

-

Custom Geometries: With LMP, creativity knows no bounds. You can design nuanced shapes swiftly, letting you spin your artistic vision into reality without the hassle of lengthy processes.

The Future of Soft Robotics and 3D Printing

As we peek into the crystal ball, the future of soft robotics and 3D printing glimmers with promise. Both of these innovations represent more than just cool tech; they signify a seismic shift in our capabilities. They hold the potential to elevate industries, from medical practices to construction, shaping our world in exciting new ways.

Next Steps and Future Directions

Looking forward, Dr. Qiao’s team has their eyes set on increasing the metal nanoparticle proportion in their creations to boost the performance of those hybrid soft robots even further. Imagine a world where medical rehabilitation products become astonishingly advanced, making those fine distinctions in care matter to patients’ everyday lives. And in a grander scope, blending AI into scientific endeavors, as seen in MIT’s churning of innovative agents, could spur a rapid expansion of fresh hypotheses and advancements across materials science and robotics.

Conclusion

By intertwining the strengths of animal physiology with groundbreaking 3D printing techniques, we’re embarking on an exhilarating journey into the realm of medical robotics and beyond. The progress we’re witnessing isn’t just a technological marvel—it's an evolution that promises to change healthcare, manufacturing, and perhaps the very essence of innovation itself.

Want to stay up to date with the latest news on neural networks and automation? Subscribe to our Telegram channel: @channel_neirotoken. Embracing these pioneering technologies paves the way for a future where we push the boundaries of imagination, exploring uncharted territory where biology and engineering collide in extraordinary ways. It’s a thrilling ride worth jumping on!